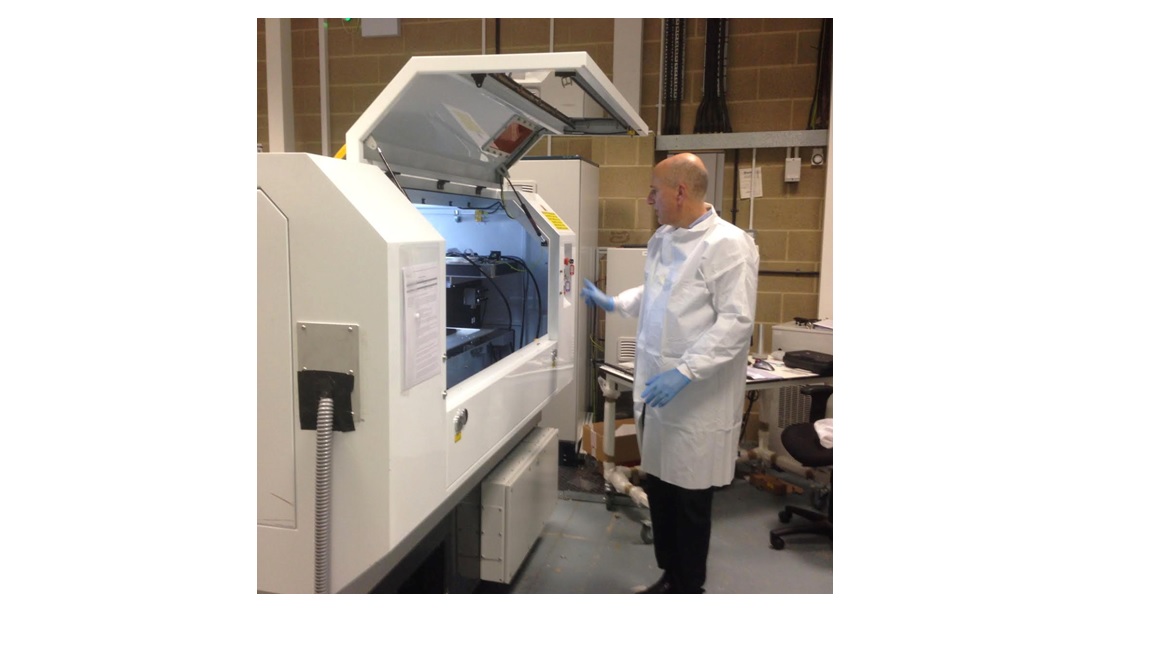

Tom Mood, a member of the Airing development team, adjusts the settings on a laser micromachining system in the manufacturer's facility.

I want to share that we have overcome one of the biggest barriers to our progress: securing access to the critical equipment we need so that we can control our own destiny! When you are working hard to get a technology developed and a product out the door and into the hands of the people who desperately need it, you must do many things in parallel. We have been doing just that, from the very start. But we have been frustrated by the limited access to a laser system, which is critical to the fabrication of key components such as the mirco-blowers.

Explaining the Problem

The tiny parts of the micro-blowers are made by a laser micromachining system. These laser systems are very expensive, costing up to $1,000,000 or even more. Our strategy, as a small startup company, was to buy time on one of these systems at an outside company. We did find a suitable subcontractor to perform the laser micromachining on the micro-blowers and we were able to turn out our first parts for testing early this year, but this took longer than expected. Development is an iterative process and by July we announced that the latest revision of micro-blowers could blow air, an exciting milestone, but later than expected. The cause of these delays had one thing in common, our reliance on an outside service where we had no priority access to the laser micromachining system. This had to change!

Creating a Solution

Because of your tremendous support and enthusiasm, a number of world class companies have approached Airing with interests in helping us develop, manufacture and deliver our micro-CPAP device to the millions of people who need it. One such company has put, right in our hands, priority access to the laser micromachining system we need, 24 hours a day, 7 days a week. Now, finally, we can really accelerate the iterations and push to a working prototype.

The Consequence

With priority access to the necessary equipment we can at last work at a quick and steady pace. Our original estimated timeline on Indiegogo showed prototyping being completed by 3/16, but given where we are now, this is likely to be more like 3/17. This delay pushes the product shipping out to 7/18; a year delay, as shown on the Revised Estimated Timeline on Indiegogo. And while the development of the micro-blowers has been slower than we planned, we have always been working on other aspects of the Airing device. For example, even further refinements of the nose buds have been made. Another strategic business relationship – this one with a brand-name battery company – can provide Airing with zincAir battery expertise. And prototyping of several other key components of the Airing micro-CPAP device is complete.

A Promise

Now that we have removed our biggest constraint, access to equipment, we will push relentlessly to make up time. We will continue to make progress in our parallel efforts: testing, sensing, battery, manufacturing, and other components. And we will continue to keep you up to date.

We sincerely appreciate your patience, and assure you that it will be worth the wait.

- Stephen Marsh and The Airing Team